| IN A NUTSHELL |

|

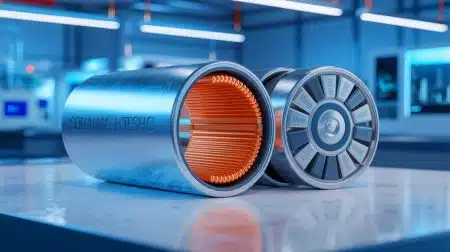

A team of researchers from the University of California, San Diego, has developed a groundbreaking method to enhance the performance and safety of lithium metal batteries. This innovation relies on a common imaging tool known as scanning electron microscopy (SEM) and a newly developed algorithm. The research aims to address the challenges faced by lithium metal batteries, which are crucial for the future of electric vehicles and large-scale energy storage systems. By providing a more reliable measure of lithium deposition uniformity, this method could significantly extend battery life and improve safety.

The Challenge of Lithium Morphology

One of the primary obstacles in advancing lithium metal batteries is the issue of “lithium morphology,” which refers to how lithium deposits on the electrodes during charging and discharging cycles. Uniform lithium deposition is critical for ensuring a longer battery lifespan. However, uneven deposits can lead to the formation of dendrites, dangerous spikes that can pierce the battery’s separator and cause short circuits.

Historically, researchers have judged the uniformity of lithium deposits by visually analyzing microscope images. This subjective approach has resulted in inconsistencies across different laboratories, hindering collaborative progress in the field. As Jenny Nicolas, a materials science and engineering Ph.D. candidate at the UC San Diego Jacobs School of Engineering, noted, “What one battery group may define as uniform might be different from another group’s definition.” The lack of a standardized language to describe lithium morphology has been a significant barrier to advancing battery technology.

Recognizing this challenge, the researchers developed a new method to create a common language for defining and measuring lithium uniformity. This innovation is a critical step toward overcoming the long-standing hurdles in lithium metal battery development.

Introducing the Index of Dispersion

The research team has unveiled a simple yet powerful algorithm that leverages SEM images to generate a concrete measurement known as the Index of Dispersion (ID). This process begins with capturing detailed, two-dimensional images of a battery electrode’s surface using SEM. These images are then converted into black and white pixels, where the white pixels represent active lithium deposits.

An algorithm divides the image into sections, counts the white pixels in each section, and calculates the ID score. As Nicolas explained, “The index of dispersion is a measure of lithium uniformity. The closer it is to zero, the more uniform the lithium deposits. A higher value means less uniformity and more clustering of lithium particles in certain areas.”

The research team validated their method by testing it on over 2,000 computer-generated images, confirming that the calculated ID scores matched the known data. This breakthrough provides researchers with a consistent way to measure and compare battery performance across different laboratories.

Implications for Battery Performance and Safety

The new method has far-reaching implications for improving battery performance and safety. By providing a more accurate measure of lithium deposition uniformity, researchers can better predict and prevent battery degradation. In tests, the team observed key signs of trouble in degrading batteries, such as increased energy required for lithium deposition and fluctuations in the ID score.

These findings suggest that the ID score could serve as an early warning indicator for potential short circuits. As batteries begin to fail, consistent peaks and dips in the ID score may signal impending issues. This capability allows for proactive measures to be taken, potentially extending battery life and preventing hazardous failures.

The accessibility of this method is another significant advantage. Since SEM imaging is already a standard tool in battery research, the new algorithm can be easily integrated into existing workflows. This makes it a practical solution for researchers aiming to enhance battery technology.

Future Prospects and Research Directions

The publication of these findings in the Proceedings of the National Academy of Sciences marks a significant milestone in battery research. The development of the Index of Dispersion opens new avenues for further exploration and innovation. Researchers can now pursue more targeted studies to refine lithium deposition techniques and improve battery performance.

Looking ahead, the team hopes to explore additional applications of their method beyond lithium metal batteries. The principles underlying the Index of Dispersion could be adapted to other types of batteries and energy storage systems, broadening the scope of its impact. Collaborations with industry partners may also facilitate the translation of this research into commercial applications.

As the demand for electric vehicles and renewable energy storage continues to grow, innovations like this one are crucial for meeting future energy needs. By overcoming long-standing challenges and providing a pathway for safer, more efficient batteries, this research represents a promising step toward a sustainable energy future.

The development of the Index of Dispersion is a testament to the power of interdisciplinary research and collaboration. As battery technology continues to evolve, what new challenges and opportunities will emerge in the quest for sustainable energy solutions?

Did you like it? 4.5/5 (23)

This is fascinating! Could this new tool be used to improve other types of batteries too? 🔋🤔

How reliable is the Index of Dispersion in real-world applications? 🤨

Thanks for the great article! It’s good to see progress in battery safety. 🔍

Are there any potential downsides to using this new algorithm? Just curious!

Finally, something that could make EVs much safer! 🚗💥

So, when can we expect to see safer EVs on the road?

Is this algorithm patented? Would love to see open-source collaboration on this!

Why didn’t someone think of this sooner? Seems like a no-brainer with SEM technology already available.

Great read! How soon could this impact consumer products?

I hope this will also help reduce the cost of EVs. We’d all benefit!