| IN A NUTSHELL |

|

The demand for precious metals essential for battery production is on the brink of soaring alongside the rise of clean energy technologies. As we look to the future, recycling spent batteries emerges as a promising solution for metal procurement. Researchers at Rice University have developed a groundbreaking battery recycling process with a metal recovery efficiency exceeding 98%. This innovative method could revolutionize how we approach battery recycling, reducing environmental impact and meeting future metal demands.

Innovative Process for Battery Recycling

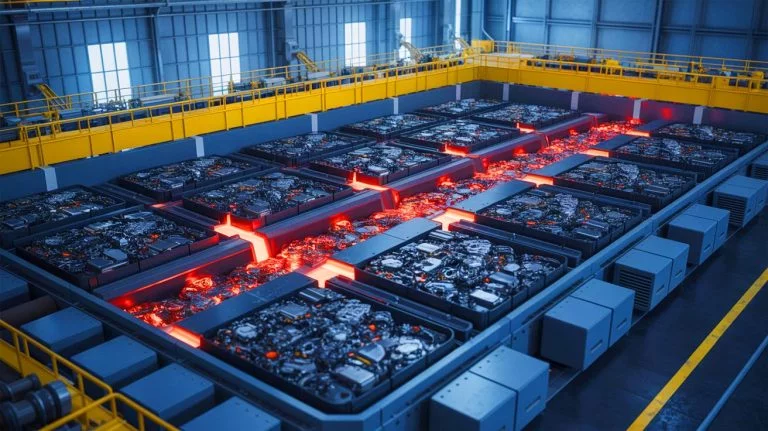

Scientists at Rice University have pioneered an innovative battery recycling process that effectively strips the inert layer off battery metals, reducing their oxidation state, and rendering them soluble in weak acids. The key to this advancement is their signature Joule heating technique, which rapidly elevates the combined waste of cathodes and anodes to temperatures over 3,400 degrees Fahrenheit in mere seconds. Led by chemist James Tour, this technique has achieved over 98% metal recovery from various mixed battery waste types.

The method, developed in collaboration with Jinhang Chen, a graduate student in chemistry at Rice, offers a high-yield, low-cost approach to metal recovery directly from the “black mass,” a challenging mixture of cathode and anode waste. This process significantly reduces the environmental footprint associated with processing used batteries. The inventive use of Joule heating not only simplifies the recycling process but also enhances the sustainability of battery production by maximizing metal recovery.

Reducing Secondary Waste and Accelerating the Process

This new method not only minimizes secondary waste streams from contaminated acidic leaching solutions but also cuts the recycling process time by almost 100 times. According to Jinhang Chen, the process can dissolve comparable quantities of metals in less than 20 minutes, as opposed to the 24 hours required by traditional methods.

Weiyin Chen, a former graduate student in chemistry at Rice and co-author of the study, highlighted the potential of this method to reduce recycling costs by decreasing energy, water, and acid consumption, alongside cutting carbon dioxide emissions. The method stands out as an eco-friendly alternative in the recycling industry, offering significant environmental and economic advantages. By streamlining the recycling process, this approach holds promise for addressing the challenges of battery waste management efficiently.

Impact on the Battery Recycling Market

The introduction of this process could invigorate the battery recycling market, a sector poised for rapid growth as batteries powering electric vehicles and other electronics reach the end of their lifecycle. James Tour, a professor of chemistry and materials science and nanoengineering at Rice, emphasized the critical importance of battery recycling in today’s context.

Beyond reducing the environmental impact of mining, recycling spent batteries is economically advantageous. The concentration of metals such as cobalt and nickel is often higher in lithium-ion batteries than in natural ores, making recycling a more resource-efficient option. This technological advancement could not only meet the increasing demand for precious metals but also catalyze a shift toward sustainable practices in the battery industry, aligning with global sustainability goals.

In Summary

The rising demand for precious metals essential for battery production calls for innovative solutions, and the recycling method developed by Rice University researchers stands at the forefront. By removing the inert layer on battery metals and reducing their oxidation state, this technique allows for the dissolution of metals in weak acids, achieving a remarkable recovery rate of over 98%.

This groundbreaking process not only promises to bolster the battery recycling market but also offers an environmentally beneficial alternative to traditional mining, making battery production more economically viable. As industries strive for sustainability, this advancement could be a key player in shaping the future of metal recovery and recycling.

The pursuit of efficient and sustainable battery recycling methods is more critical than ever. As we look to the future, how will this innovation influence global approaches to resource management and environmental conservation?

Did you like it? 4.5/5 (22)

Wow, 98% recovery rate? That’s impressive! 🔋

How does Joule heating compare to other recycling methods in terms of cost?

This sounds like a huge step forward for clean energy! 🌿

Are there any potential downsides or environmental impacts from using this new technique?

Does this mean we’ll see cheaper batteries soon? 🤔

Great article! Thanks for sharing this breakthrough. 👍

I’m curious, how does this process handle different types of batteries?

Is there a video of this Joule heating technique in action? 🔥

Finally, some good news about recycling! 🙌

Rice University really seems to be leading the charge in battery tech. Impressive!

How scalable is this process? Can it be used in large recycling facilities?